Ak-Pres A.Ş. an automotive supplier corporation within the Küçükoğlu Holding was founded in 1990.

With its 50,000 m2 of covered area factories in Sakarya and Bursa, Ak-Press has been serving shaped metal sheet parts to the world's giant car brands with thousands of jobs it provides are among Turkey's first 1,000 industrial organizations. In the sheet metal forming area, hosting investments within the latest technology in parallel with the automotive industry, sustainable growth, quality and continuous development of the sector with a staff committed and Turkey continue to contribute confidently towards the economy.

OUR MISSION

While serving the automotive industry in manufacturing and services using every resource effectively with our knowledge and experience;

• To ensure unconditional customer satisfaction

• To meet the expectations of society, environment, and our stakeholders.

OUR VISION

To be in Fortune Turkey’s 500 list by 2025, with manufacturing high technology body and chassis parts to the automotive industry.

OUR VALUES

- Respect to Humanity

- Equality

- Transparency

- Reliability

- Work Safety

- Environmental Impact

- Honesty

WORK HEALTH AND SAFETY POLICY

With the objective of our Occupational Health and Safety (OHS) policy, we ensure that our employees work in an environment that is in line with the health and safety conditions of our employees and reach an accident-free workplace through the "Safety First" principle;

- To acquire and develop the knowledge that a healthy and safe working environment is an indispensable part of life,

- Prevent injuries and health deterioration,

- Ensuring that all healthcare and safety requirements are implemented by our managers, ensuring compliance and continual improvement,

- To comply fully with the safety rules in all our activities,

- Resolve the risk of all our employees, including our guests and subcontractors, with the idea of ensuring their safety,

- To comply with all legal requirements within the context of employee health and safety,

- We promise to announce our OHS policy to all persons working on behalf of Ak-Pres and to keep it open to cover all relevant organizations at all times.

Akpres R & D Center continues to experience the knowledge gained through projects that are co-operating with the main industries in cold metal sheet shaping, mechanized and welded parts design and manufacturing with R & D projects based on a systematic basis.

As a result of these studies, our company was entitled to get the R & D Center title by the Ministry of Science, Industry and Technology on 16.06.2011.

Akpres conducts the following duties in R&D activities with its experienced and expertized employees;

Product and mechanism development

Weight Lightening

Alternative materials

Passenger & pedestrian safety

Equipment design

Universal Traction Test Machine (UTM)

- Maximum Load: 5 Tones

- Control interval of testing speed: 0.1 m/min ~ 30 m/min

- Digital display of test data

Constant heat & humidity test

- Constant cycle test function

- Test heat interval: -40℃ ~ 100℃

Salt spray test

- Testing heat: 0~35℃

- Air lily spraying

- Ph, Digital display of salt level

Hardness Test

- Rockwell hardness measurement

- HRC,HRB outputs

Fatigue Test

- Product specific test system

- Test heat interval: -40℃ ~ 100℃

3D Measurement

- 1500x850x850 mm capacity

- Real time 3D CAD interaction

Product specific performance test equipment are available.

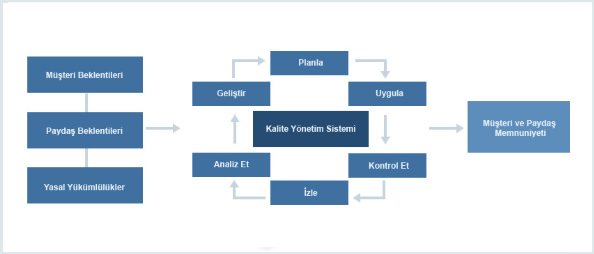

In the context of transformation, we have launched, we have gathered our activities in the areas of environmental, social and corporate governance under the slogan of "Sustainability". In pursuing our performance in all areas under sustainability, we have identified stakeholder analysis issues that need to be addressed primarily.

When determining our issues, we mainly referenced customer feedback and sectoral sustainability trends. We see our employees as our social priority to increase their satisfaction by providing a healthy, safe and happy business environment.

Moving in an innovative framework with research and innovation is the building block of all our processes. A production environment that respects human rights is among the indispensable ones, and it is at the top of our targets to spread to the precious supply chain that we have.

To establish and maintain a relationship of trust and respect between employees and management based on the principle of human dignity for the existence, integrity and the future of our group of companies, to provide the environment in which all employees are responsible and constantly improve themselves and contribute to their personal development.

With the DATATECH Academy, all the employees in the organizations are defined the DATATECH standards, on equal terms, the professional, personal development, managerial training needs and the training programs that will meet these needs are being created. All employees of the DATATECH family can participate in these programs.

Every employee in the organization is considered to be a specialist of the job they are doing, and the training needs are correctly determined and put into practice. Our leadership programs aim to train leaders with strategy-oriented, awareness in their business processes, high quality work, tomorrow's added value.

Nilüfer Köy Mahallesi Nilüfer Caddesi No: 172, 172/1

Osmangazi/Bursa, TURKEY

(+90) 224 219 29 50

(+90) 224 244 88 53

2. OSB 2 Nolu Yol No:20

Hendek/Sakarya, TURKEY

(+90) 264 654 59 19

(+90) 264 654 57 66